The production machines of ELEC composite material division has two main types: 1) Compression molding machines range from 80 tons to 1500 tons. 2) Transfer molding machines range from 60 tons to 400 tons. For post- production, various automation is adopted including automated burring machine, ultra-sonic cleansing machine etc. We have both capacity and technology to fulfill various customers need.

ELEC has various precision testing equipment used for material development, type tests of new product, incoming check of raw material, production control and shipment qualification.

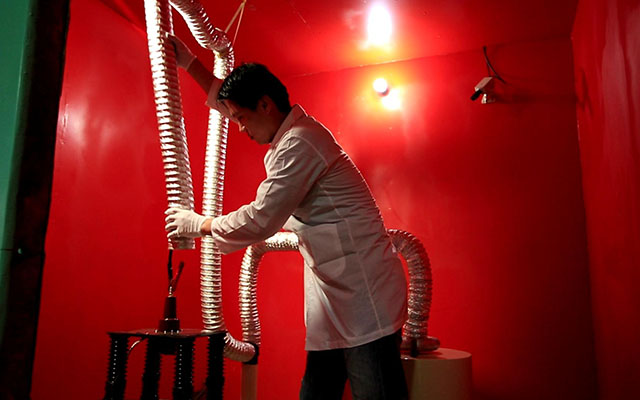

Physical testing equipment includes for tests of flowability, water absorption, material shrinkage, heat curing, burn resistance, thermal deformation etc.

Mechanical testing equipment includes 1 tons, 5 tons and 50 tons universal testing machine which can be used for various bending tests, tensile tests, compression tests and torque tests etc.

Electrical testing equipment includes dry and wet arc-resistance testing machine, 100kV dielectrical machine, 300kV impulse resistance machine and 50kV partial discharge machine.

We also have X-ray machine to detect internal defect of products, 3D coordinate measuring equipment to measure complicated dimensions, hand-held X-ray analysis machine to analyze various metal components and inserts as well as ULVAC helium leakage detection machine to ensure tightness of sealing.